Contact Numbers

Print and apply labeling is a process used in the packaging and labeling industry that involves printing labels on demand and then applying them to products or packaging materials. This process can be automated using a print and apply labeler, which can increase efficiency and accuracy in labeling applications.

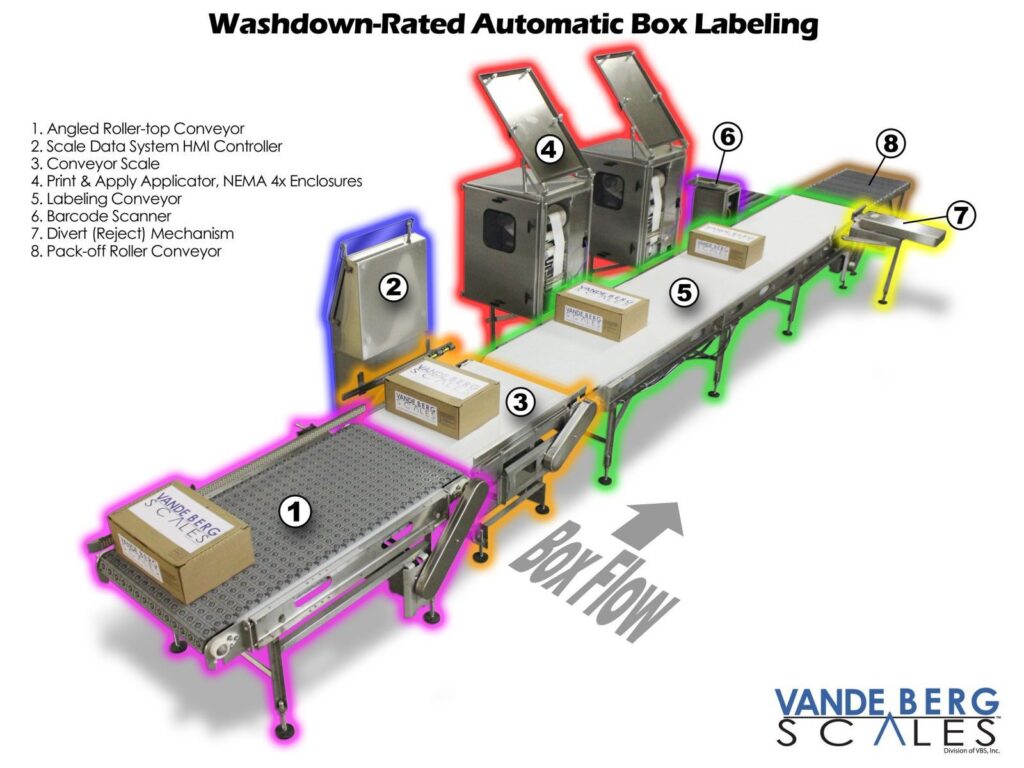

The print and apply labeler works by first printing the label on a thermal transfer printer, which uses heat to transfer ink onto the label material. The label is then automatically dispensed from the printer and applied to the product or packaging material using a labeling applicator. The applicator can be a variety of types, including tamp, blow, or wipe-on applicators.

Print and apply labeling systems can be used in a variety of applications, such as in the food and beverage industry, pharmaceuticals, and logistics. They are particularly useful in applications where variable data, such as serial numbers, lot numbers, and barcodes, need to be printed on the labels.

Benefits of print and apply labeling systems include:

Increased efficiency: Print and apply labeling systems can automate the labeling process, reducing the need for manual intervention and improving efficiency.

Improved accuracy: Print and apply labeling systems can ensure that labels are applied accurately and consistently, reducing the risk of errors and improving product quality.

Versatility: Print and apply labeling systems can be used for a variety of label types and sizes, and can handle a wide range of products and packaging materials.

Compliance: Print and apply labeling systems can help companies meet regulatory requirements by ensuring that labels are applied accurately and contain the required information.

Overall, print and apply labeling systems can help companies improve their labeling processes, increase efficiency, and improve product quality.